Answer: Because they are Handcrafted.

Answer: Because they are Handcrafted.

All signs and plaques from Atlas have some variances in the final product. These wonderful indications of hand finishing are most prevalent on Copper Verdi, Bronze Verdi, and Iron Rust.

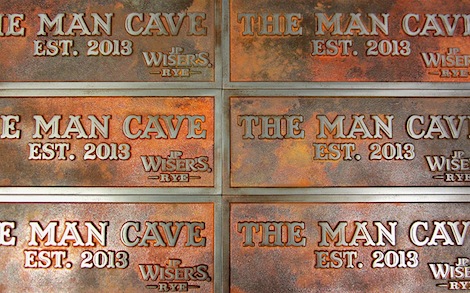

The photo above is a really good representative photo of how custom finishes vary from piece to piece. These Man Cave Signs are all the same except that each one is different from the one right next to it. For more cool Iron Rust Photos visit the Atlas Pinterest Iron Rust Board.

They were all completed on the same day within a very short time span. The process used to patina the iron into the “aged look” was the same on each plaque. So how can each on be different? The patina process contains several steps and several different compounds. Each of these are applied by hand and therefore are not exactly the same.

Additionally, the final polishing step is 100% by hand allowing for even more of the character that we desire.

All metal finishes from Atlas are what we call “Living Finishes“, meaning that they change naturally over time. While all finishes are “Living”, the Verdigris and Iron Rust finishes are more alive than the others.

We hope this was helpful. Here are more information on Real Metal Finishes from Atlas Signs and Plaques.